PRODUCTS

研发生产自动化设备产品

联系我们

CONTACT US

手机/微信:15327312169

联系热线:15327312169

电子邮件:huayuegaojing@163.com

公司传真:

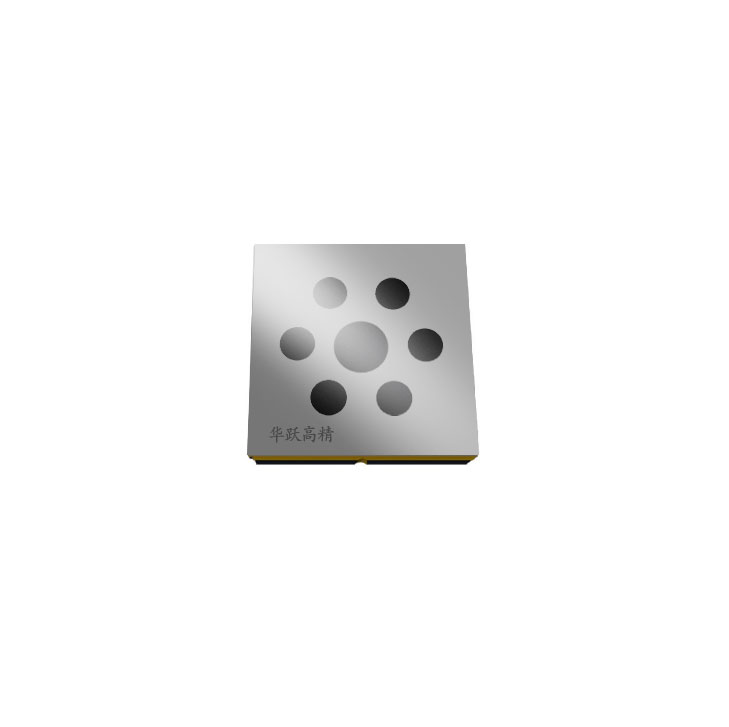

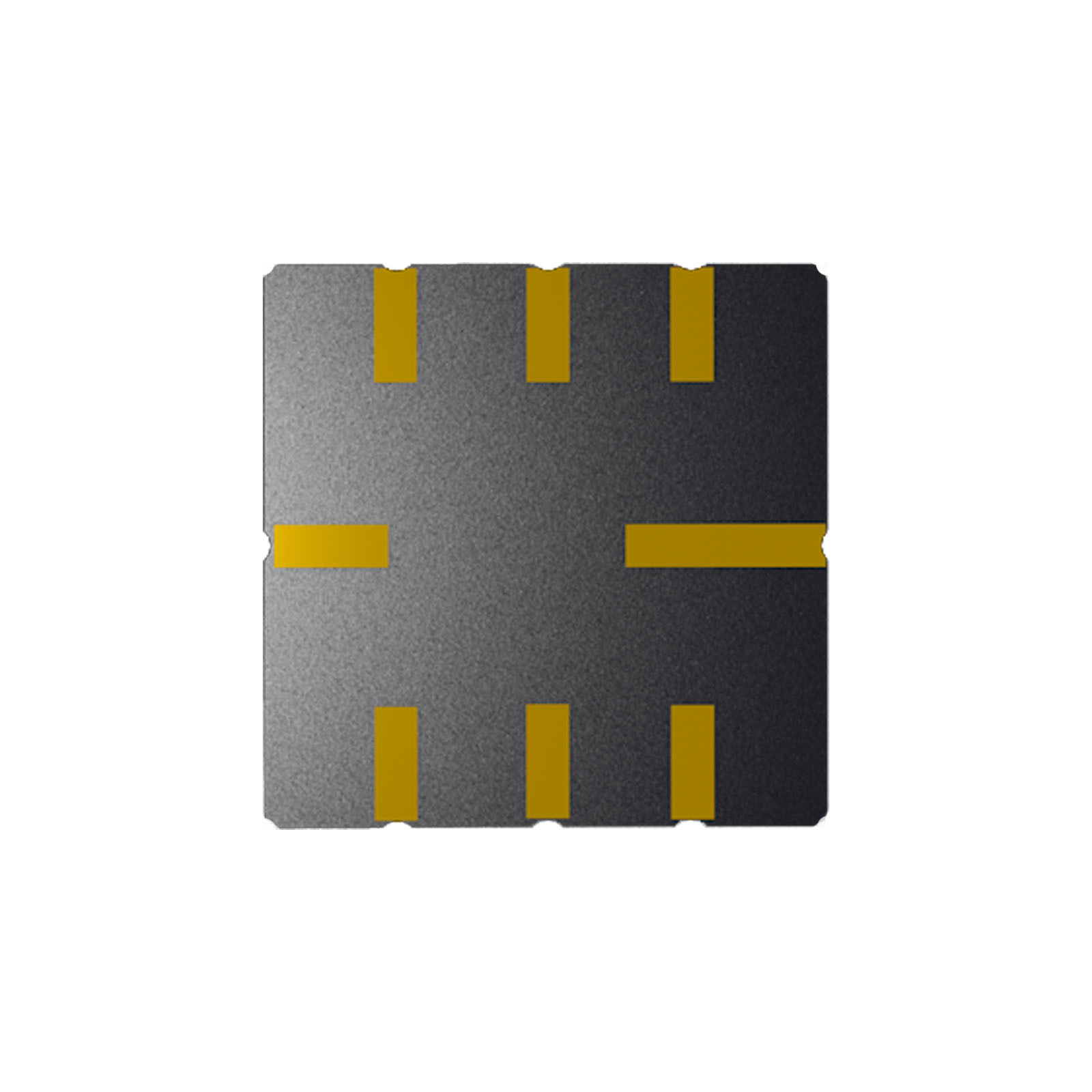

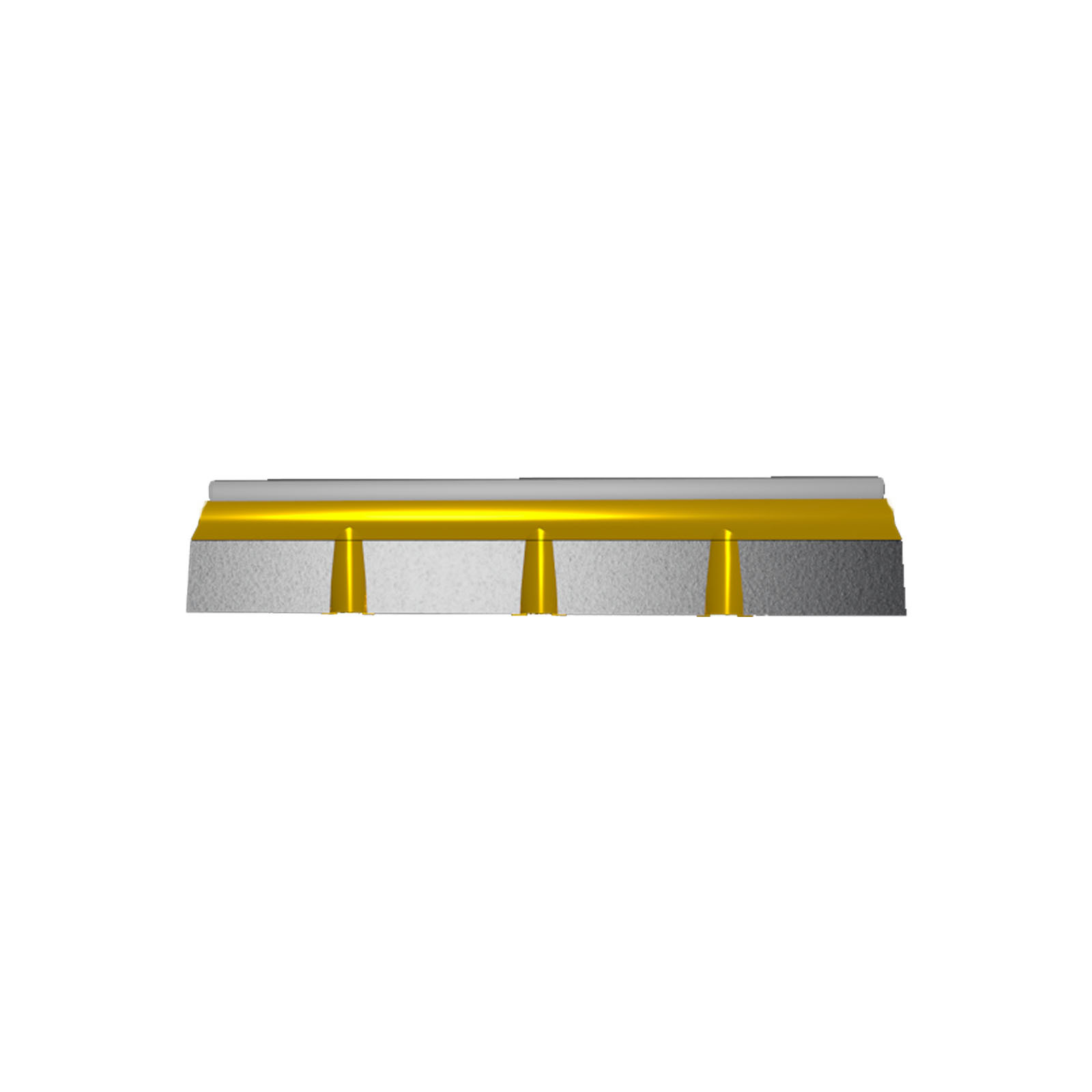

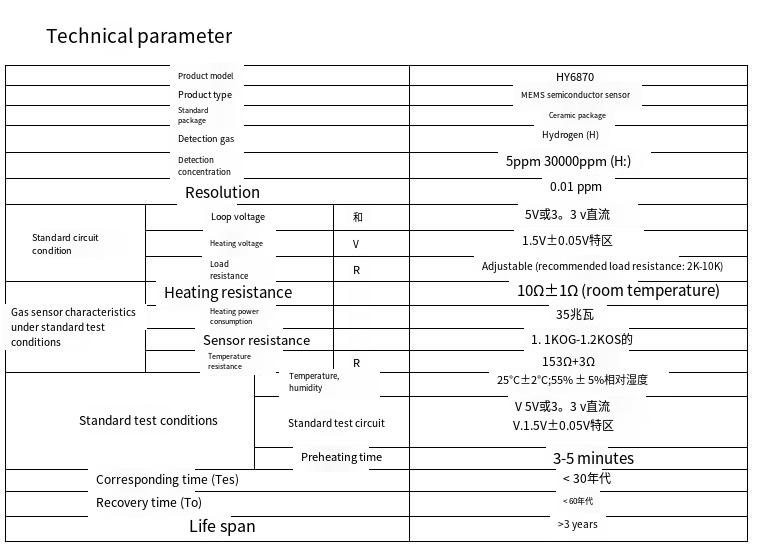

HY6870- Hydrogen sensor

售价: 9元

立即购买First, product introduction

HY6870 Hydrogen gas sensor is a MEMS micro gas sensor based on specific semiconductor gas sensitive materials, which can be used to detect hydrogen gas content in different scenarios.

Second, sensor characteristics

MEMS process, semiconductor material, small size, low power consumption, high sensitivity, fast response recovery, simple drive circuit, good stability, long life, strong structure, good shock resistance.

Precautions;

1, must avoid the situation

1.1 Exposure to volatile silicon compounds vapor Sensors should avoid exposure to silicone adhesives, hair gels, silicone rubber, putty or other places where volatile silicon compounds are present. If the surface of the sensor absorbs silicon compound vapor, the sensitive material of the sensor will be coated with silicon dioxide formed by the decomposition of silicon compounds, which inhibits the sensitivity of the sensor and cannot be recovered.

1.2 Highly corrosive environmental sensors exposed to high concentrations of corrosive gases (such as SOX, Cl2, HCl, etc.) will not only cause corrosion or destruction of heating materials and sensor leads, but also cause irreversible deterioration in the performance of sensitive materials.

1.3 The pollution sensor of alkali, alkali metal salt and halogen is polluted by alkali metal, especially brine spray, or exposed to halogens such as freon, which will also cause deterioration in performance.

1.4 Contact with water Splashing or immersion in water will cause the sensor sensitivity to decrease.

1.5 Frozen water icing on the surface of the sensor sensitive material will cause the sensitive layer to break and lose the sensitive properties.

1.6 Applying too High a voltage If the voltage applied to the sensor or heater is higher than the specified value, even if the sensor is not physically damaged or destroyed, it will cause damage to the lead and/or heater and cause degradation of the sensor sensitivity.

1.7 Voltage Error Pin If the sensor or heating and signal pin voltage error, will also cause damage to the lead and/or heater, and cause sensor sensitivity reduction.

2. Avoid situations where possible

2.1 Condensate Under indoor conditions, slight condensation will have a slight impact on sensor performance. However, if the water condenses on the surface of the sensitive layer

And held for a period of time, the sensor characteristics will decline.

2.2 Whether the sensor is powered on or not in high concentration gas, long-term placement in high concentration gas will affect the characteristics of the sensor. If the lighter gas is sprayed directly into the sensor, it will cause great damage to the sensor.

2.3 Long-term storage When the sensor is stored for a long time without power, its resistance will produce reversible drift, which is related to the storage environment. sense

The device should be stored in a sealed bag free of volatile silicon compounds. Sensors that have been stored for a long time need to be energized longer before use

Make it stable. The storage time and corresponding aging time are recommended as follows:

2.4 Long-term Exposure to extreme environments Regardless of whether the sensor is powered on, long-term exposure to extreme conditions, such as high humidity, high temperature or high pollution, will seriously affect the performance of the sensor.

2.5 Frequent vibration, excessive vibration will cause the sensor internal lead resonance and fracture. The use of pneumatic screwdriver/ultrasonic welders in transit and on assembly lines can produce such vibrations.

2.6 Impact If the sensor is strongly impacted or dropped, its lead will break.

2.7 Conditions of Use:

2.7.1 Manual welding is the most ideal welding method for sensors, and the recommended welding conditions are as follows; Rosin flux with minimal chlorine

2.8 ESD Prevention

Violation of the above conditions of use will degrade the sensor characteristics